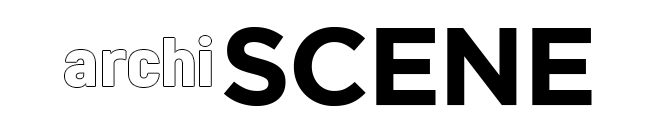

Striatus, the first 3d concrete printed bridge, is a collaborative project by the Block Research Group (BRG) at ETH Zurich and Zaha Hadid Architects Computation and Design Group (ZHACODE), in collaboration with incremental3D, made possible by Holcim. Discover more after the jump.

Establishing a new language for concrete, Striatus is circular by design, combining traditional masonry with advanced technologies.

Strength through geometry

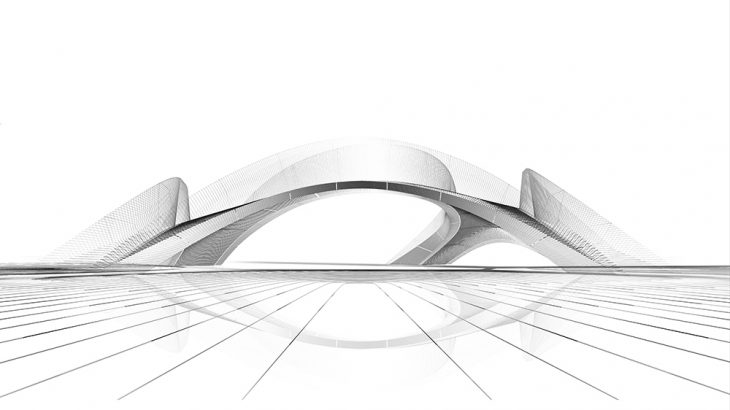

Achieving strength through geometry, the Striatus bridge stands solely through compression without reinforcement. Using advanced technologies, from computational design and engineering to robotic manufacturing, Striatus revives traditional master builders’ techniques.

Circular by design

Striatus was designed to place material only where needed, significantly reducing its environmental footprint. With no reinforcement and using dry assembly without binders, it can be repurposed repeatedly.

A new language for concrete

Striatus opens up a world of possibilities with concrete in a design that is structurally informed, fabrication-aware and ecologically responsible. Material is precisely placed to build more with less.

Being built for the “Time Space Existence” exhibition, hosted by the European Cultural Centre (ECC) during the Venice Architecture Biennale 2021.

Opening soon at the Giardini della Marinaressa, Venice, Italy.

Find more projects by Zaha Hadid Architects: www.zaha-hadid.com