3D printing is a beautiful piece of technology introduced to us in the 1980s. It empowers you to create physical objects more quickly than traditional production methods. Additionally, it allows you to create complicated geometries previously impossible to create in 3D, giving you the freedom to make the designs you want.

Today, you’ll be reading how the development of 3D printing technology has revolutionized architecture.

Why Architects need Scale Models

While engineers and architects usually understand how a building will turn out through blueprints, your client typically won’t have the same level of understanding. As such, it becomes vital to create a scale model so they get a better idea if it would be worth financing. Additionally, scale models let planners check if engineers can feasibly build the full-scale design.

In the past, scale models would be made of materials like wood as it’s relatively cheap and accessible. However, this method of creating models takes time — time that could have gone to improving the design or starting construction.

Rapid Prototyping

Depending on the complexity, you may need to wait several days for the scale model of the design. 3D printing solves this issue by eliminating the long person-hours required to complete your scale model, as the printing machine and computer take over the creation process.

Secondly, if you find the design unsatisfactory or detect any flaws, you can quickly remedy the design in a 3D computer environment based on your discoveries from the printed model.

Innovation

In addition to the rapid prototyping, you also get a chance to test out new ways of making your design stand out. Innovation typically takes time to develop in the construction industry, as safety usually takes top priority. You won’t have to sacrifice innovation with any surface access door hidden flange as it uses unique designs, making it easy to match form and function in any workspace.

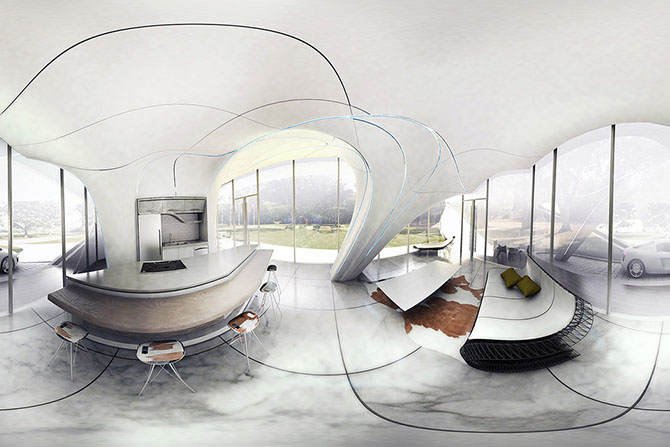

With 3D printing, you open the doors to trying out how new designs work with more conventional construction methods. Moreover, the intricate shapes you want in your final design may be impossible to do by hand. 3D printing fixes this problem since the printing method is done layer by layer, and you are given the freedom to wow your clients with your unique designs.

Cloud-Driven Collaboration

With the ubiquity of the internet, it becomes easier for you to collaborate with your teams. Gone are the days of sitting together in the same room with your team to get the job done – which was a requirement. Now, you can all pull up the same 3D design and work on it simultaneously.

You can also send the plans to your client once the design is complete, allowing them to stay in the loop during the design process.

Reducing Waste

Traditional modeling methods often require cutting down large pieces of material to fit a specific shape in the design. However, you run into a problem where you cannot use the excess fabric in the model.

The only waste would be the supporting material needed to print the product, much less than in traditional manufacturing. If being environmentally friendly is vital for you, 3D printer filament made from recycled plastics is also available. Not only do you get to do your job, but you also help the environment in the process.

Creating Copies

You may run into clients wanting multiple copies of your scale model. However, they will unlikely spend the same amount it took to create the original if you did it using conventional methods.

However, with 3D printing, you can quickly print out a copy for them. You can also introduce changes to make the model more appealing, such as integrating different colors or adding interior design details that you couldn’t include in the original.

3D Printing with Other Materials

The technology associated with 3D printing isn’t limited to only plastic. Concrete, metal, and even sand can create larger-scale pieces with larger 3D printers.

This flexibility in material choice allows you to create intricate designs with little loss in quality while enjoying the durability perks of the other materials.

Limitless Possibility

The modernization of 3D printing has come a long way from its original conception in the 1980s. Development of this tech is going at breakneck speeds by introducing more cost-effective and durable materials.

Whether you use 3D printing to create smaller scale models or 3D printed concrete to add beauty to your next project, you open yourself up to creating more complex designs that weren’t possible a few decades ago.

Images from Curve Appeal 3D-Printed House by WATG – See the full story here